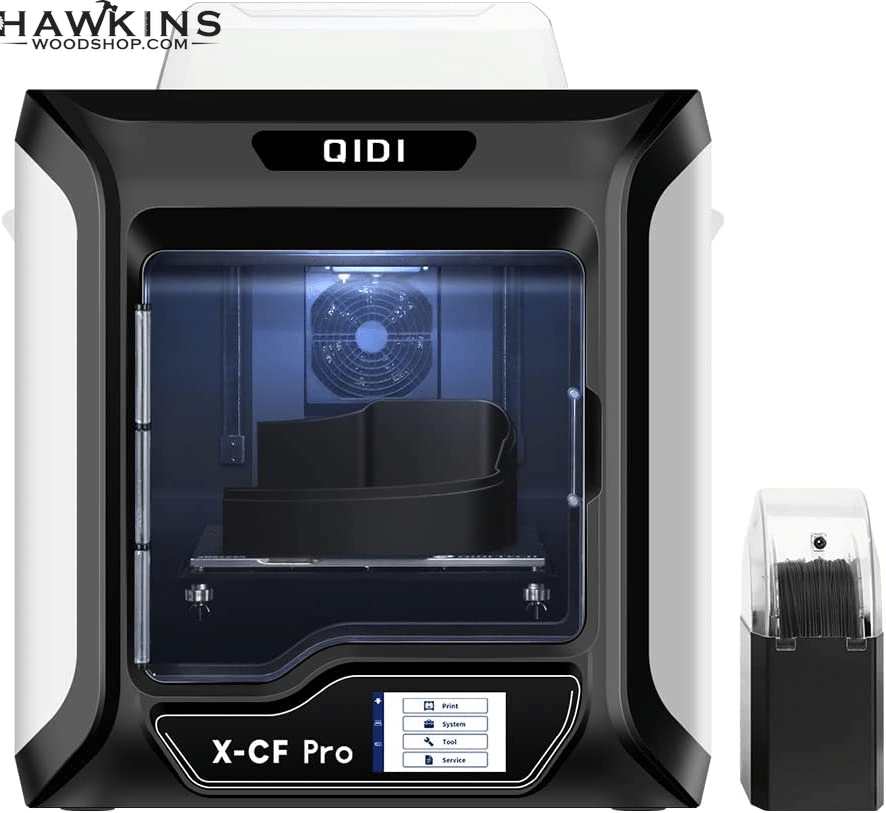

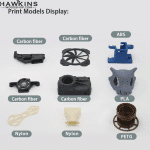

X-CF Pro 3D Printers Industrial Grade,Specially Developed for Printing Carbon Fiber&Nylon with QIDI Fast Slicer, Automatic Leveling,Large Build Volume 11.8X9.8X11.8 Inch

$1,942.98

In stock

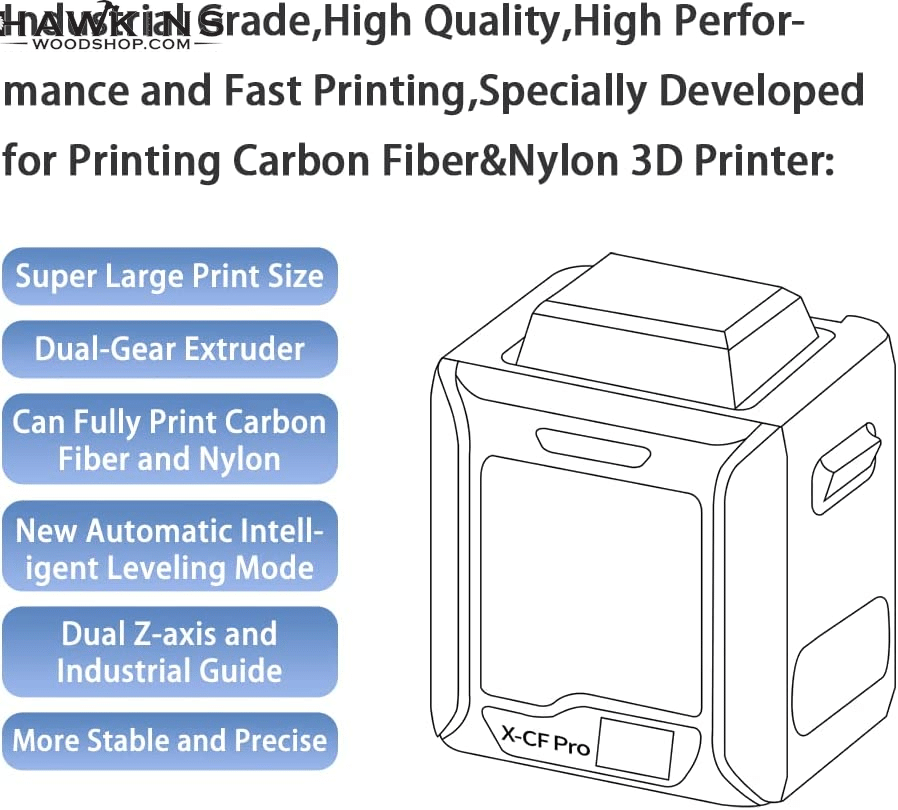

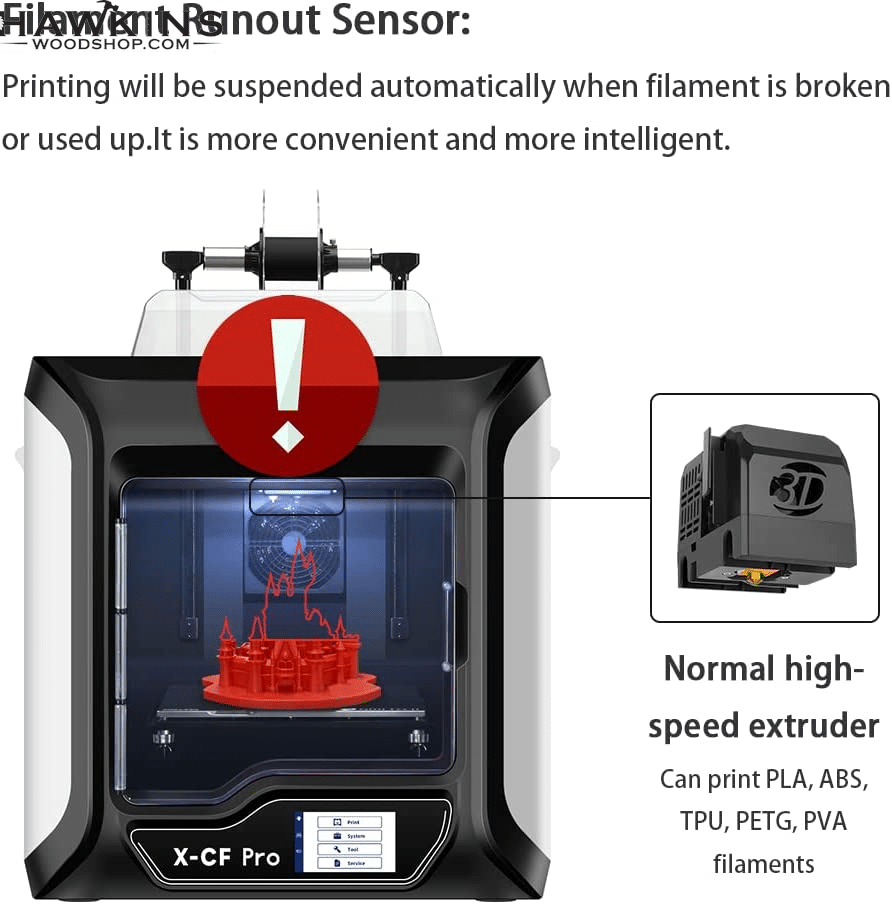

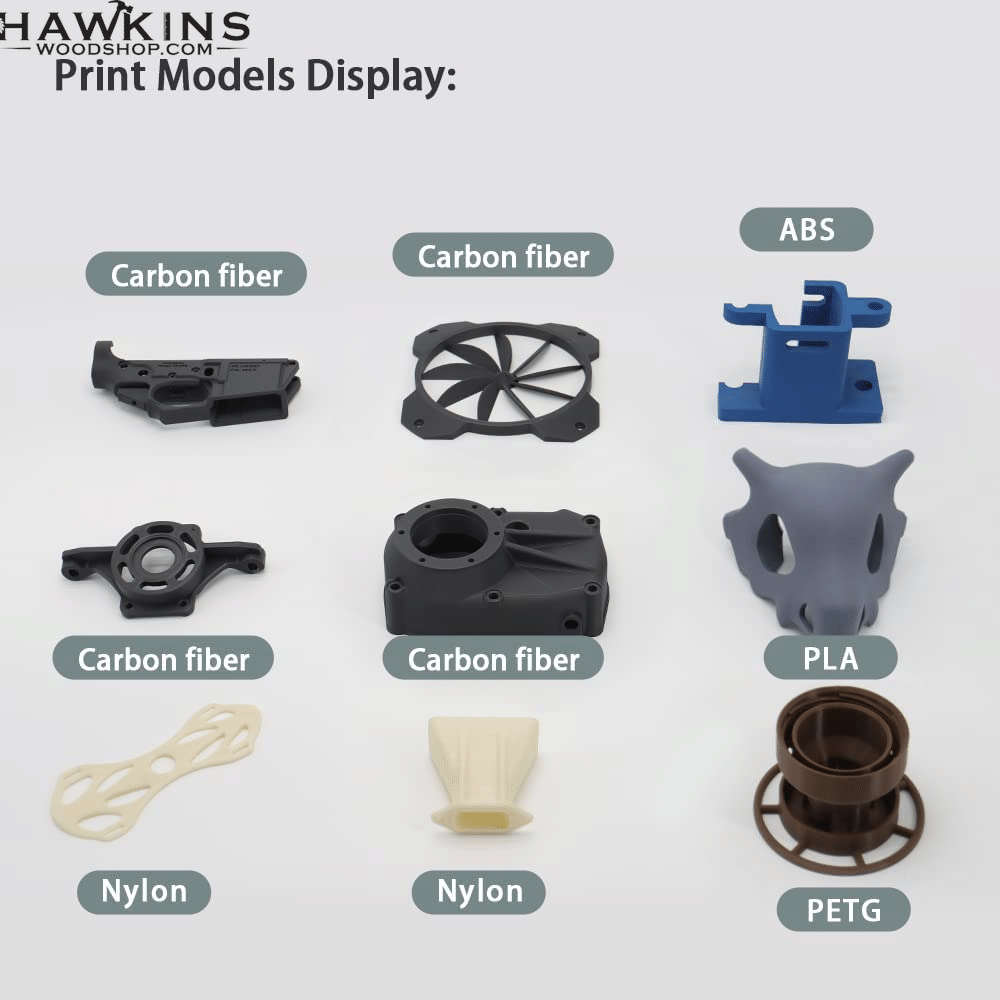

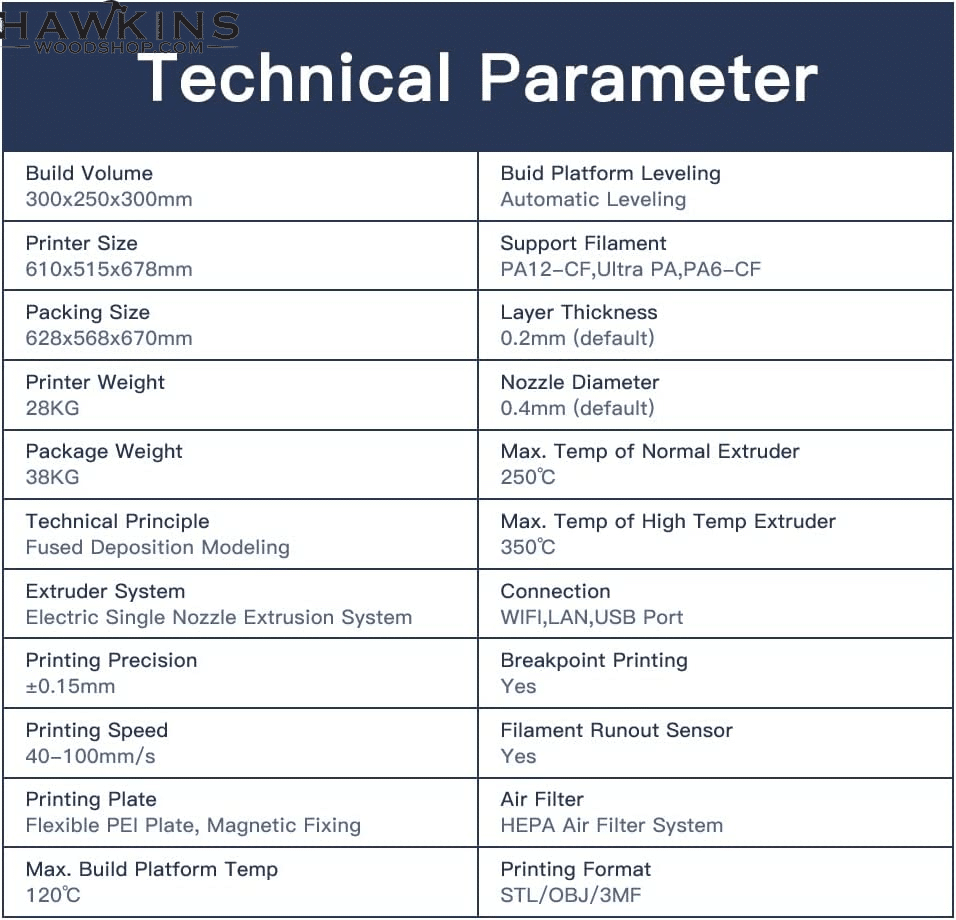

- 【Design Concept】X-CF PRO is a 3d printer specially designed for printing carbon fiber and nylon filaments.Independent research and development of the latest generation single extruder system, which uses high-temperature alloy material, dual-gear extrusion, can solve the problem of the accuracy is not very accurate or service life is not long when printing carbon fiber. Another set of normal high-speed extruder can easily print PLA, ABS, PETG and other filaments.

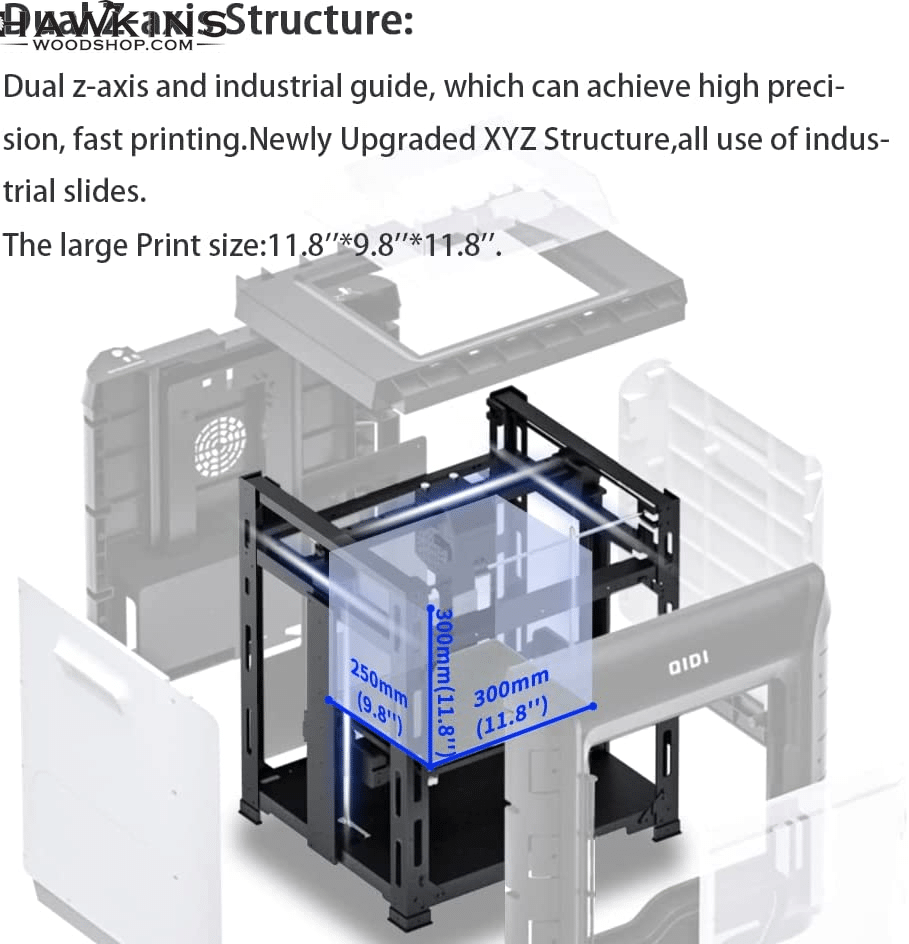

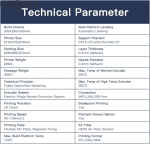

- 【Precision Manufacturing Process】QIDI TECH using industrial-grade manufacturing, dual z-axis and industrial guide, can achieve high precision, fast printing. Upgrading the XYZ structure, all use of industrial slides. PEI printing plate, solve printing models warp and other problems.The 3d printer’s structure is developed for the effective and accurate printing of carbon fiber.Meanwile, printing other common filaments, the speed can be increased to 120cc per hour.

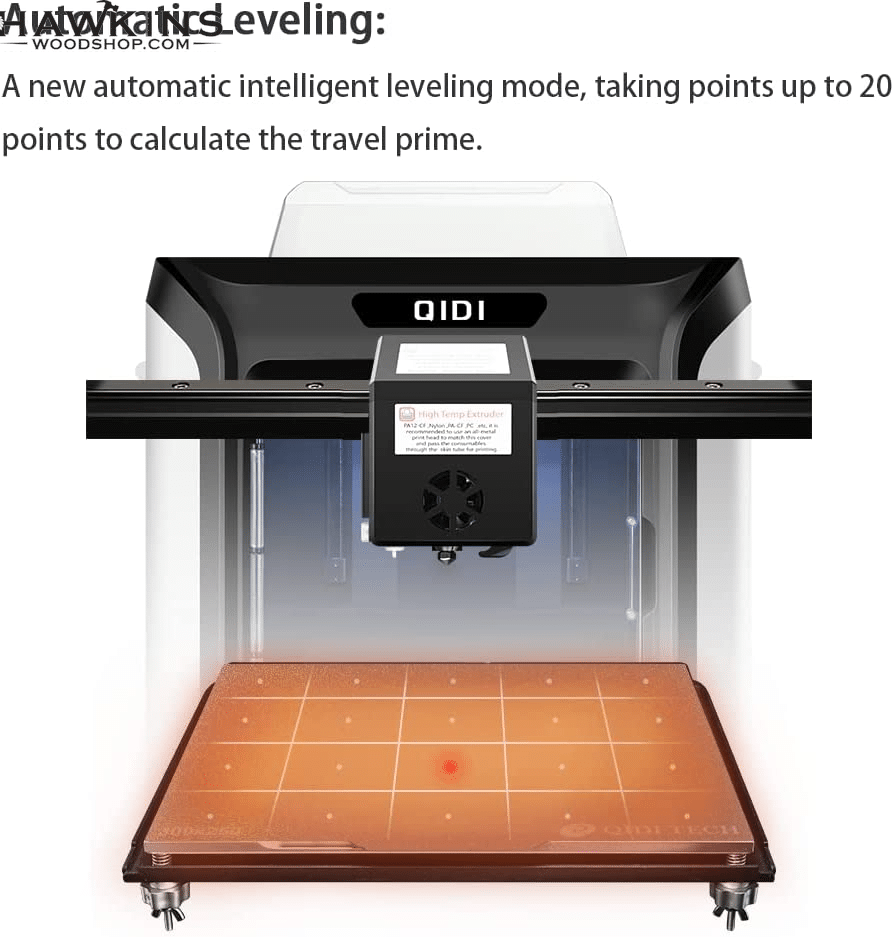

- 【New technology upgrade】 A new automatic intelligent leveling mode, taking points up to 20 points to calculate the travel prime. With the new upgraded software, it is more intelligent, especially provide more effective and accurate parameters for printing carbon fiber and nylon filaments, which can be used right out of the box. The main board is made of main core Cortex-M4 and TMC2208 driver chip, matched with 800*480mm 5 inch HD capacitive display.

- 【Professional Filament】In order to better realize carbon fiber, high temperature nylon printing. We have developed these filaments ourselves.QIDI TECH are very grateful to many professional users who have provided us with a lot of valuable information to create this 3D printer dedicated to printing carbon fiber and high-temperature nylon filaments.

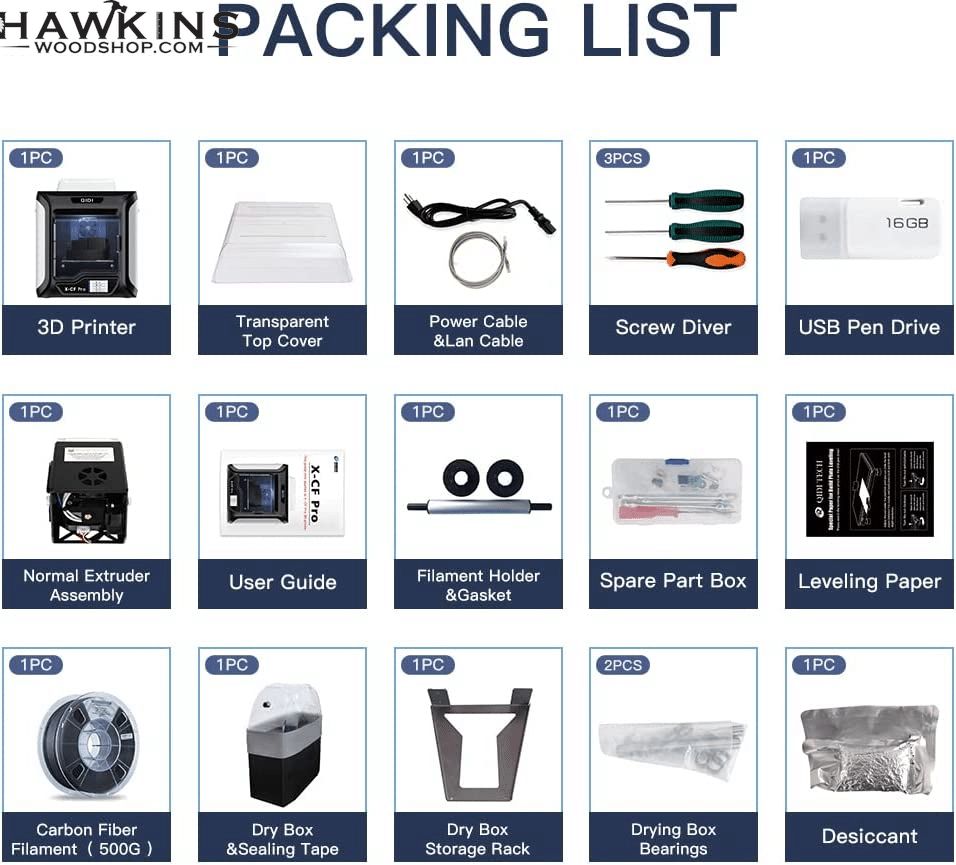

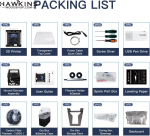

- 【QIDI TECH Service】QIDI TECH are committed to making valuable 3d printers. X-CF Pro is suitable for professional users as well as novice users.No assembly,out of the box. It is easy to print according to the operating instructions. The highly praised service of QIDI TECH is the most trustworthy. 2 year warranty(1 year + 1 extra year).

Product Description

QIDI TECH X-CF Pro 3D Printer

X-CF Pro, QIDI TECH R&D team spent 13 months developing an industrial grade FFF 3d printer that can fully print carbon fiber and nylon. We redesigned the extruder system to be more suitable for printing carbon fiber materials with a mechanical motion structure and a filament dry box. The software was redeveloped after extensive testing by Qidi Tech engineers. Many thanks to the large number of Qidi Tech users who provided us with valuable experience and information and participated in the development of the first professional printing carbon fiber and nylon 3d printer on Amazon.

Carbon Fiber

1. Smart Fiber Reinforced Technology

It greatly improves the mechanical properties and heat resistance of the material, and releases the internal stress during the printing process through the fiber mesh structure, resulting in good dimensional stability of the printed part and no warpage.

2.Low Moisture Sensitivity

PA12-CF based on modified PA12 long-chain nylon, whose saturated moisture absorption rate is only one tenth of ordinary PA6, completely solving the defects of the mechanical properties and dimensional stability of nylon materials that change greatly after absorbed moisture.

3.Low Density

PA12-CF is the one of the lowest density FDM industrial printing material, which can easily meet the high strength and lightweight requirements of industrial applications.

4.Super Abrasive Resistance

PA12-CF has a low coefficient of friction, self-lubricating properties and excellent wear resistance, which can easily meet all kinds of high-strength gears or industrial applications with high wear requirements.

UltraPA Nylon filament

1.Low Moisture Sensitivity

UltraPA based on modified high temperature nylon, whose saturated moisture absorption rate is only one tenth of ordinary PA6, completely solving the defects of the mechanical properties and dimensional stability of nylon materials that change greatly after absorbed moisture.

2.Strongest layer bonding performance

UltraPA have the best layer strength,the layer adhesion of single wall structure is 2-3 times of ABS material and 1.5 times of PLA material.

3.Super Abrasive Resistance

UltraPA has low coefficient of friction, self-lubricating properties and excellent wear resistance,which can easily meet all kinds of high-strength gears or industrial applications with high wear requirements.

Newly Upgraded XYZ StructureIndustrial-grade manufacturing, dual z-axis and industrial guide, which can achieve high precision, fast printing. Focus on upgrading the XYZ structure, all use of industrial slides. | Industrial Extrusion StructureOne set of high temp extruder, with the latest generation single extruder system, which uses high-temperature alloy material, dual-gear extrusion. Specifically for printing carbon fiber, high temp nylon filaments. Another set of normal high-speed extruder can easily print PLA, ABS, PETG and other filaments. | Filament Runout SensorDetection System, more convenient, more intelligent. |

Automatic LevelingA new automatic leveling mode. Realize fully automatic leveling. | PEI Material PlateThe printing plate using PEI material, effectively solve the problem of printing models warp and other problems. Better adhesion, the printer’s overall life is longer. | 5.0 inch Touch Screen800*480mm 5 inch HD capacitive display. Larger interface makes it more intuitive and easy to operate. | Slicing SoftwareThe Qidi Tech latest generation slicer software version 6.5.1 With the new upgraded software, it is more intelligent, especially provide more effective and accurate parameters for printing carbon fiber and nylon filaments, which can be used right out of the box. |

| Technology | Fused Deposition Modeling | Fused Deposition Modeling | Fused Deposition Modeling | Carbon Fiber filament | Filament Dryer Box |

|---|---|---|---|---|---|

| Build Volume | 10.6”x7.9”x7.9”(270x200x200mm) | 11.8”x9.8”x11.8”(300x250x300mm) | 11.8”x9.8”x11.8”(300x250x300mm) | Diameter:1.75mm | Maximum Capacity:Φ210*85.5(H)mm |

| Filament Types | PLA,ABS,TPU,PETG,Nylon,PC,Carbon fiber,etc | PLA,ABS,TPU,PETG,Nylon,PC,Carbon fiber,etc | Carbon fiber,Nylon,PLA,ABS,TPU,PETG,etc | ||

| Platform Support | Double Z axis | Double Z axis | Double Z axis | ||

| Extruder Configuration | 1 set of professional printing PLA, ABS TPU high stability extruder, Add 1 set of high performance extruder for printing PC, Nylon, Carbon fiber. | 1 set of professional printing PLA, ABS TPU high stability extruder, Add 1 set of high performance extruder for printing PC, Nylon, Carbon fiber. | 1 set of professional printing PLA, ABS TPU high stability extruder, Add 1 set of high performance all metal high temp extruder for printing Carbon fiber,Nylon. | ||

| Printing Plate | heated, removable plate | heated, removable plate | heated, removable plate | ||

| Support | 1-Year | 1-Year | 2-Year | ||

| Filament Diameter | 1.75mm | 1.75mm | 1.75mm | ||

| Printing Extruder | Single Extruder | Single Extruder | Single Extruder | ||

| Layer Thickness: | 0.05mm-0.4mm | 0.05mm-0.4mm | 0.05mm-0.4mm |

NON CUSTOM FURNITURE

Delivery for imported, manufactured furniture by our production partners is FREE NATIONWIDE!

No costly prime membership is required nor is any bogus minimum order amount required.

Delivery time varies based on the product but is typically 2-5 business days, but may be up to 4+ weeks for large freight items like couches.

LOCALLY MADE TO ORDER, SOLID WOOD FURNITURE

Average turn-around time from date of purchase till pick-up or delivery of a made to order solid-wood furniture purchase is 4-6 weeks. Turn-around may be as short as 2 weeks and as long as 12 weeks.

Nearly all custom furniture orders may be picked up for free within 60 miles of any metropolitan area in the continental United States.

However, local delivery for custom furniture is also available!

Cost for custom furniture delivery is based on your proximity to your personal Hawkins Woodshop furniture artisan. You are assigned and introduced to your HW carpenter after purchase. Delivery cost is paid directly to your HW personal furniture artisan 2-3 days prior to scheduled delivery via any payment method you chose (Venmo, Zelle, PayPal, FB Pay, Check, Cash, Credit Card, etc).

Built-to-order furniture delivery rates are:

< 20 miles = $89.97

21-45 miles = $129.97

46-74 miles = $189.97

75-100 miles = $269.97

101-130 miles = $349.97